This report is a tree structure kind of drill down report. Report Information.

Select the “Lot Serial Track” link under the “DP Reports”.

The “Lot Serial Track” page appears.

Enter the following fields:

|

Item Code |

The code identifying the item |

|

Lot No. |

The code identifying the lot number to which the item belongs to. |

|

Serial No. |

The code identifying the serial number to which the item belongs to. |

|

From Issue Date |

The starting date in the range of issue dates from which you want to view the lot serial track report details. The system date is displayed by default on launch of the page. |

Note: The date entered in this field must be equal to or less than the date entered in the “To” field.

|

To Issue Date |

The ending date in the range of issue dates to which you want to view the lot serial track report details. The system date is displayed by default at the launch of the page. |

Note: The date entered in this field must be equal to or greater than the “From Date” field.

|

From Receipt Date |

The starting date in the range of receipt dates from which you want to view the lot serial track report details. The system date is displayed by default on launch of the page. |

Note: The date entered in this field must be equal to or less than the date entered in the “To” field.

|

To Receipt Date |

The ending date in the range of receipt dates to which you want to view the lot serial track report details. The system date is displayed by default at the launch of the page. |

Note: The date entered in this field must be equal to or greater than the “From Date” field.

The system displays the following in the “Search Results” multiline:

|

Serial No. |

The code identifying the serial number to which the item belongs to. |

|

Lot No. |

The code identifying the lot number to which the item belongs to. |

|

Ref. Doc. No. |

The document number against which the lot or serial number item was received in inventory. |

|

Doc. Type |

The type of the document. |

|

Receipt Qty. |

The quantity received by Inventory on the date for the lot or serial number item. |

|

Issue Qty. |

The quantity issued by Inventory on the date for the lot or serial number item. |

|

Transaction Date |

The date on which the lot or serial number item was issued by the inventory. |

|

Customer Code |

The code identifying the customer. |

|

Vendor Code |

The code identifying the vendor. |

Enter the following fields:

|

Option |

Use the drop-down list box to select the option in which the production and shipment history report is to be viewed. You can select from “Track Down” or “Track Up”. The system displays “Track Down” by default on launch of the page. The system displays “Track Down” by default on launch of the page. The options available are: |

|

|

|

|

|

Production History |

Select this check box to view the production report details. The system first retrieves and displays the inventory details followed by the production history details in the form of tree control. Selection of each node in the tree will retrieve and display the lot or serial details. |

|

Shipment History |

Select this check box to view the shipment report. The system first retrieves and displays the inventory details followed by the shipment details. |

Click the “Lot Track” pushbutton to view the lot details for the selected item.

The system generates the lot track report details based on the track up or track down option for the selected lot number in the multiline.

Click the “Serial Track” pushbutton to view the lot details for the selected item.

The system generates and displays the report based on the following conditions:

If the item code is specified, then the system retrieves and displays the lot or serial numbers pertaining to that item code in the multiline.

If the lot number is specified, then the system retrieves and displays the lot numbers in the multiline.

If From Receipt Date and To Receipt Date are specified, then the system retrieves and displays all the lot or serial number items that are received between these two dates in the multiline.

If From Issue Date and To Issue Date are specified, then the system retrieves and displays all the lot or serial number items that are issued between these two dates in the multiline.

If more than one criterion is specified then the system retrieves and displays all the lot or serial number details that match all the criteria.

If no search criteria are specified then the system refreshes the screen and does not retrieve any lot or serial number item details.

Lot Serial Track – An Overview

This report summarizes the lot and serial tracking of the items from goods receipt to sales shipment and from sales shipment to goods receipt. This report gives you the complete picture of production or shipment history along with the inventory transactions. The report is generated for the selected lot or serial number. This report helps you to diagnose the quality problems when reported by the vendors based on the sales or inventory receipts. This report also provides a complete tracability within the company.

The tracking of lot or the serial numbers is possible in two ways:

4 Track Down – Displays the details of all the input item lot or serial numbers for the selected lot number.

4 Track Up – Displays the details of all the end item lot or serial numbers in which the selected lot or serial number is an input item.

Along with the above options, production history or shipment history options can be selected to view the report accordingly. The lot serial track report is generated based on the following options.

4 Production History – Displays the lot or serial numbers in the form of a tree structure. On selecting each of the lot or serail number, first the inventory details are displayed then the production history details are displayed.

4 Shipment History – Displays production receipt and sales return details as a part of inventory report. Issues made against the pack slip along with the invoice quantity are displayed as a part of production history report.

This page allows you to set the criteria to generate the report for tracking the lot or the serial numbers. You can specify the item for which the lot or serial numbers are to be traced. You can generate a lot or serial track report for a specific issue or receipt date or for a range of issue or receipt dates. You can also specify the lot number or the serial number that forms a part of the criteria. Based on the criteria specified, the system retrieves the lot or the serial details in the multiline.

You can select the record(s) in the multiline and can choose the appropriate tracking option. The report can be viewed in two ways. Production report explodes the inventory transactions and the production history transactions. Sales report explodes the inventory transactions and the sales history transactions.

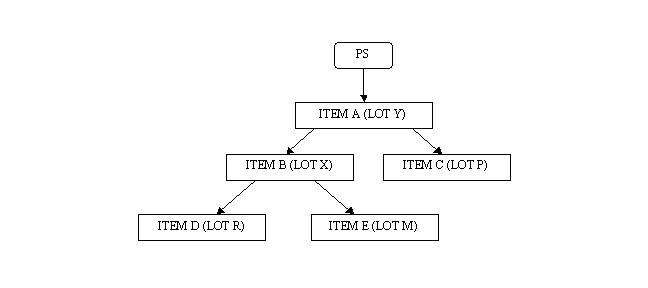

For example, consider a product structure with Item A, Item B, Item C, Item D and Item E with the corresponding lot numbers at various levels as depicted below:

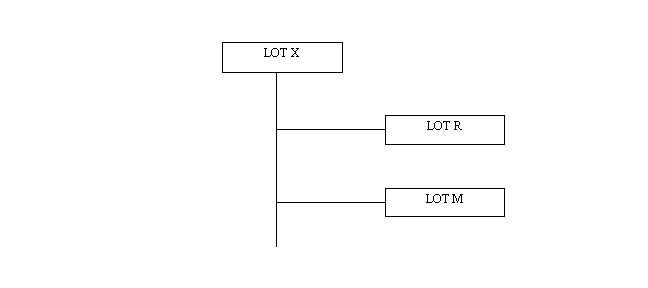

§ In the above chart, if LOT X with the “Track Down” and “Lot Track” options is selected, a tree like structure as depicted below is generated:

If LOT R or LOT M or LOT X is selected, first the inventory transactions are displayed then the production transactions are displayed in the form of report.

If Shipment History option is selected with the above options, first the inventory transactions are displayed then the sales transactions are displayed in the form of report.

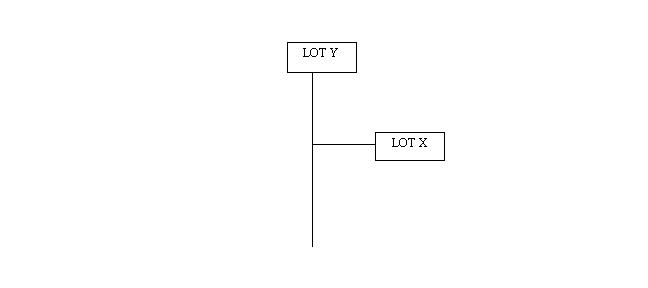

§ In the above chart, if LOT X with the “Track Up” and “Lot Track” options is selected, a tree like structure as depicted below is generated:

If LOT Y or LOT X is selected, first the inventory transactions are displayed then the production transactions are displayed in the form of report.

If Shipment History option is selected with the above options, first the inventory transactions are displayed then the sales transactions are displayed in the form of report.

Note: The above logic also applies to serial number tracking. In such case, along with the “Track Down” and “Track Up” options “Serial Track” option must also be selected.